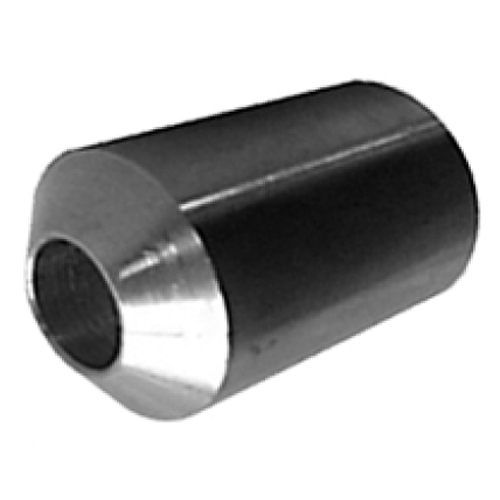

Forged Welding Boss

Forged Welding Boss Specification

- Material Grade

- Various Grades Available

- Corrosion Resistant

- Yes

- Features

- High Quality

- Surface Finish

- Polished

- Material

- Stainless Steel

- Connection

- Welding

- Standard

- AISI

- Surface Treatment

- Galvanized

- Color

- Different Available

- Warranty

- 1 Year

- Usage

- Pipe Fittings

Forged Welding Boss Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Forged Welding Boss

Application Surface Excellence of Forged Welding Boss

Forged Welding Boss adapts seamlessly to an array of application surfaces, proving indispensable for pipe fittings across industrial and commercial settings. Its polished, galvanized surface finish ensures compatibility with diverse installation environments. Suitable for both smooth and rugged application surfaces, this boss sustains reliable sealing with fluids or gases as the application media. Reduced risk of corrosion and seamless welding connection foster heightened operational efficiency and longevity on every applied surface.

Main Export Markets and Packaging: Reliable Supply for Global Exchange

As an acclaimed global supplier, our forged welding boss is exchanged extensively in international markets. The best-in-class product is supplied to destinations across Asia, Africa, Europe, South America, and the Middle East. Each boss is packaged meticulously, reducing expenditure on damage control during transit. With robust supply ability supporting large-scale demand, we ensure reliable delivery and cost-effective exchange of goods, reinforcing trust and satisfaction among partners worldwide.

FAQs of Forged Welding Boss:

Q: How is the forged welding boss installed in pipe fittings?

A: The forged welding boss is welded directly onto pipe surfaces, ensuring a secure and seamless connection as part of the fitting assembly.Q: What are the benefits of a galvanized and polished surface on this welding boss?

A: Galvanized and polished surfaces provide superior corrosion resistance, reduced wear, and enhanced appearance, thereby prolonging product life and maintaining performance in challenging conditions.Q: When is it advisable to use different material grades for a welding boss?

A: Different material grades should be selected based on the intended application, media type, pressure, and temperature requirements to ensure optimal compatibility and longevity.Q: Where can these forged welding bosses be applied most effectively?

A: They can be used effectively in industrial, commercial, and municipal piping systems where high-quality and corrosion-resistant weld connections are essential.Q: What is the process for ensuring quality and durability in these welding bosses?

A: We employ stringent manufacturing standards, use superior stainless steel, and incorporate galvanized finishes, followed by rigorous quality checks to ensure each boss meets industry benchmarks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Fitting Category

Buttweld 90Deg Long Radius Elbow

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Corrosion Resistant : Yes

Connection : Butt Fusion

Usage : Pipe Fittings

Material Grade : Various Grades Available

Stainless Steel Weld Union Socket

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Corrosion Resistant : Yes

Connection : Welding

Usage : Pipe Fittings

Material Grade : Various Grades Available

Tube Coupling

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Corrosion Resistant : Yes

Connection : Welding

Usage : Pipe Fittings

Material Grade : Various Grades Available

Butt Weld Pipe Bend

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Corrosion Resistant : Yes

Connection : Butt Fusion

Usage : Pipe Fittings

Material Grade : Multiple Grades Available

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese